Sparks, flames and smoke. All of these have been a common sight along the steel spiral staircase of Oodi in recent weeks. Extensive welding work is in progress, as the stairs, which were delivered to the site as 10 separate blocks, will now be attached together with thick welded seams. The seams, visible as dark vertical lines on the white railing, will of course be covered with paint. At this time next year, the library customers will be using the stairs without a hitch, moving from the lobby up to the third floor.

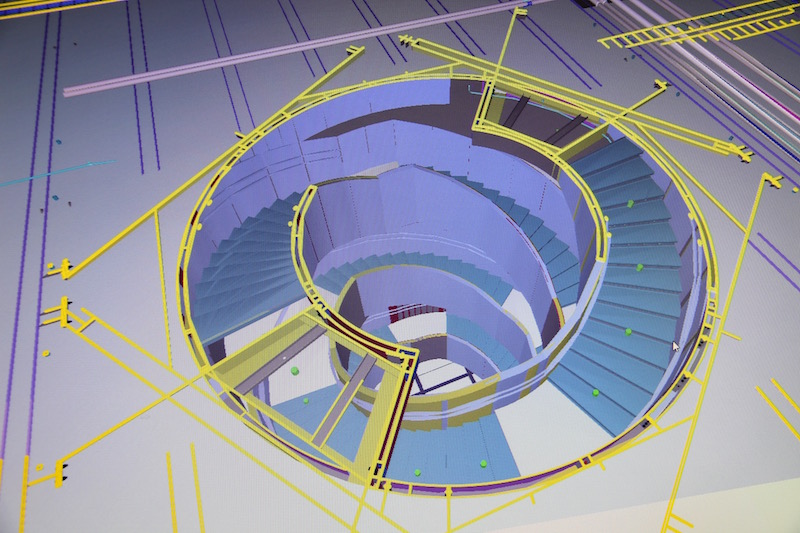

The spiral staircase of Oodi is both impressive and structurally unique. The complex consists of two spirals, which resemble the structure of DNA. It seems like this structure is hanging in mid-air, as it does not seem to have any support at the bottom and there is no support pillar in the middle. This magic trick will be accomplished by supporting the stair complex through the structures of the floor slabs.

“During welding, we are still using temporary supports, but after they are removed the staircase will be supported by the floor slabs. In part, this solution increases the frame’s load, which will grow further when the stairs are used by the library customers. We have taken the pressure and movements of the building into account: some seams allowing movement have been left in the library structures,” says YIT’s site manager, Janne Kurikka.

Proof of excellent work planning is the fact that the entire stairwell has been protected with tarpaulins from the bottom to the top, forming a tent. This means that the assembly work and the particles generated by welding do not disturb those working close by and the odour also stays in the tent around the stairwell. The goal is to complete the welding work by the beginning of April.

Facade will be clad with spruce

In April, Oodi’s appearance will start to change visibly. There are two reasons for this: the entrance floor will receive its facade windows and the outer surfaces’ final cladding work will be started.

The main entrance area, with its curving shapes, is a challenging area for cladding. Whereas straighter walls are quick to clad using elements, curving surfaces as well as the edges of various holes and gaps have to be covered using individual pieces. On the eastern side of the building, wooden cladding will be accompanied with aluminium plates.

Spruce was selected as the material of the wood cladding, says Site Manager Janne Kurikka, who is in charge of the frame and the facade. In the photo, he is holding a model piece of the cladding.

“The cladding consists of laths, but viewed from afar the surface will seem like a smooth wooden surface. Before starting the installation, the material will go through fire testing. A batch of wood treated with fireproofing paint will be exposed to open flame, and during the test we will monitor how well the protective paint stops the wood from charring. The protection must meet certain determined values. In the future, the facade will be treated with the fireproofing paint about every fourth year.”

Janne is also personally familiar with wood construction. A while ago, he finished his own, a little under 250-square metre wooden house in Porvoo. Janne, a 33-year-old civil engineer, acted as both the project’s architect and principal designer and also worked as a constructor. His three children and five cats now have plenty of space for roaming and playing!

Cables will be covered with an installation floor

At this stage, the second floor in particular reveals the library’s ‘nerves and veins’ i.e. all the building technology that will be hidden behind walls or covered with an installation floor.

The library will feature a restaurant and two cafés, but the users of the small group working rooms on the second floor will also have their own kitchen. Its electric lines and sprinkler system pipes will soon be covered with an installation floor. The lighting installations on the second floor are also progressing well. The work must be finished before installing the installation floor, as it is not able to bear the weight of the scissor lift.

The woodwork of the arching staircase, intended for reading and working, is almost finished. After mid-March, plywood covers were put in place, and in the next stage the staircase will be covered with grey textile carpet.

Third floor waiting for its suspended ceiling

The children’s area in the northern end of the third floor is being prepared for the installation of the white, curving suspended ceiling. The model piece installed in the middle of the third floor in the beginning of the year has been approved and the work will proceed based on the experiences of its installation.

Currently, the ceiling of the children’s area is covered with hanging steel poles of various lengths, which will later hold the suspended ceiling. Gradually, it will cover the ceiling’s ventilation pipes and maintenance bridge.

After the indoor works start, the third floor’s large windows will be protected from scratches and dirt. The windows will be covered with a film to protect them from dust and their bottom halves will be covered with EPS boards. This allows work to proceed with less risk of damage occurring.

Worksite humour in bloom in Oodi

At this stage, indoor works require the use devices intended for working with timber and plywood, which means that the song of a circular saw, for example, is a frequent thing. The amount of sawdust could be staggering, but it is controlled with special sawing premises situated on the different floors, which are tents with a door that can be closed during the work.

Work goes quicker with some humour and laughter. A subcontractor has named their sawing tent their VIP premises.

The worksite is full of rules, but sometimes a little humour can be added, even in serious matters.