Managing material streams on a narrow plot in the middle of the city is one of the challenges of the Oodi worksite. When dozens of loads arrive on the site every day, a frequently heard question is ‘where should we put these?’ The site’s wonder woman, Heidi Järvensivu, i.e. the site manager in charge of logistics, knows the answer. She adapts her instructions to the worksite’s situation: where the goods are needed, how soon they will be needed and where there is enough space for them. The loads are taken to their correct spots in the yard or directly to the right blocks on the different floors.

“I have to always be one step ahead of the construction and consider logistics a few days in advance. I have to stay on top of the loads, building schedule and building layout at the same time. My goal is for the goods to only be moved once; they should be taken to the correct place right away,” Heidi says, with her 10 years of logistics experience backing her up.

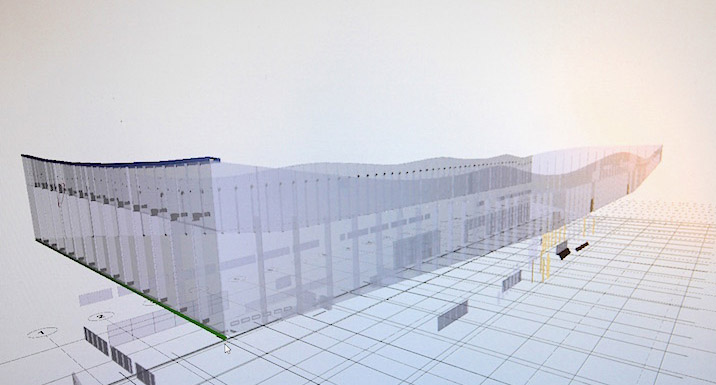

Because there is a street on the eastern side of the building, only the western side can be used for storing goods. A small part of Kansalaistori square is also utilised as storage space. In October, one of the loads that arrived contained a large shipment of bricks for the brickwork of the rooms. They are shown as the white pile in the middle of the lower part of the photo. Space is needed for many different goods, such as timber and pipes, ventilation and electrics installation equipment and, more and more, for the facade windows.

Heidi Järvensivu greets the drivers at the different gates. In addition to drivers bringing in loads, she gives driving instructions to drivers of, for example, concrete mixer trucks and pump trucks, as well as various crane and lifting vehicles. Heidi has grown into her position through experience, and she is a great example of entrepreneurship and problem solving.

“For years, I worked as a transport coordinator and after that as a construction painter and tiler. I noticed the same problem on many different worksites: goods were left waiting in the wrong places, communications did not work and no one managed the logistics. I decided to set up a business in the field myself and found another female entrepreneur as my partner. Local Logistics offers logistic and worksite services, which also include waste management coordination and worksite supervision. On the Oodi worksite, we work under the main developer, YIT.”

Oodi has an unusual shape, not only with regard to construction but also from the perspective of logistics. The public balcony restricts lifting of the goods, and there is a long distance between the north and south ends. It is not possible to store goods in front of the building, as the area must be kept clear for various vehicles and cranes. At this stage, the public balcony is waiting for surface concrete casting. The casting of the second-floor seating area seen behind the balcony has been completed, and the scaffolding that has supported the area has been taken down.

A freight elevator was installed at the southern end of the building in October, making it easier to transport goods to the different floors. The elevator will become more and more crucial as the facade is closed during the construction work’s progress.

Only insulation needed on the roof

The short-term objective is to insulate the building and keep its temperature above zero. In many places, expanded polystyrene insulation sheets are used in place of walls. They tolerate moisture well and act as excellent thermal insulation.

The EPS foam sheets are also used as walls on the third floor, although they will later be replaced by floor-to-ceiling windows. The third floor is reserved for books. It looks more closed off now, as the elements of the roof have been installed along the entire building.

The Oodi roof has a low ridge, and on both sides of it the roof rises and falls like waves. The curving forms were built using cut-to-shape elements nearly a metre thick. YIT’s site manager Mansoor Ardam supervised the installation work on the bitumen membrane insulation at the end of October.

The waves and ridges of the roof as well as its several skylights made the membrane installation process challenging. The membrane is attached to the surface by heating it with a gas burner.

Facade windows follow the curves of the roof

The wavy form of the roof also affects the measurements of the third-floor facade windows. Their height varies, following the rising and falling shape of the roof. The tallest, over nine-metre high windows will be installed in the eastern and western facades. They will be assembled from several elements.

“The installation work will begin from the building’s northern end. We have acquired special equipment for the lifting work, and the suction cups needed were manufactured in Italy. One, a couple of metres tall and similarly wide glass weighs a little over 1,000 kilos. From the north, the installation work will progress to the east wall,” says Mansoor Ardam.

The windows will be installed into the steel slots shown at the bottom of the photo. Estonian firm Windoor AS will both manufacture the windows and procure the printed pattern for them. The new library could not have more wonderful surroundings: the northern windows have a view of the Finlandia Hall and its park.

The window installation work on the second floor has progressed a little faster. The lined windows were installed in the northern wall in October. The installation of the walls’ thermal insulation progressed quickly from the northern end to the eastern wall. The work there has been completed and will next move towards the south.